Description

With this half automatic Slit Puncher

punched cards (ISO 7810/7813, thickness 0.5–1 mm) can be further processed

by punching holes or other forms (e.g. for GSM-SIM cards) into them and by perforating

separation lines. The cards with holes are often used as marketing articles (e.g. key tags).

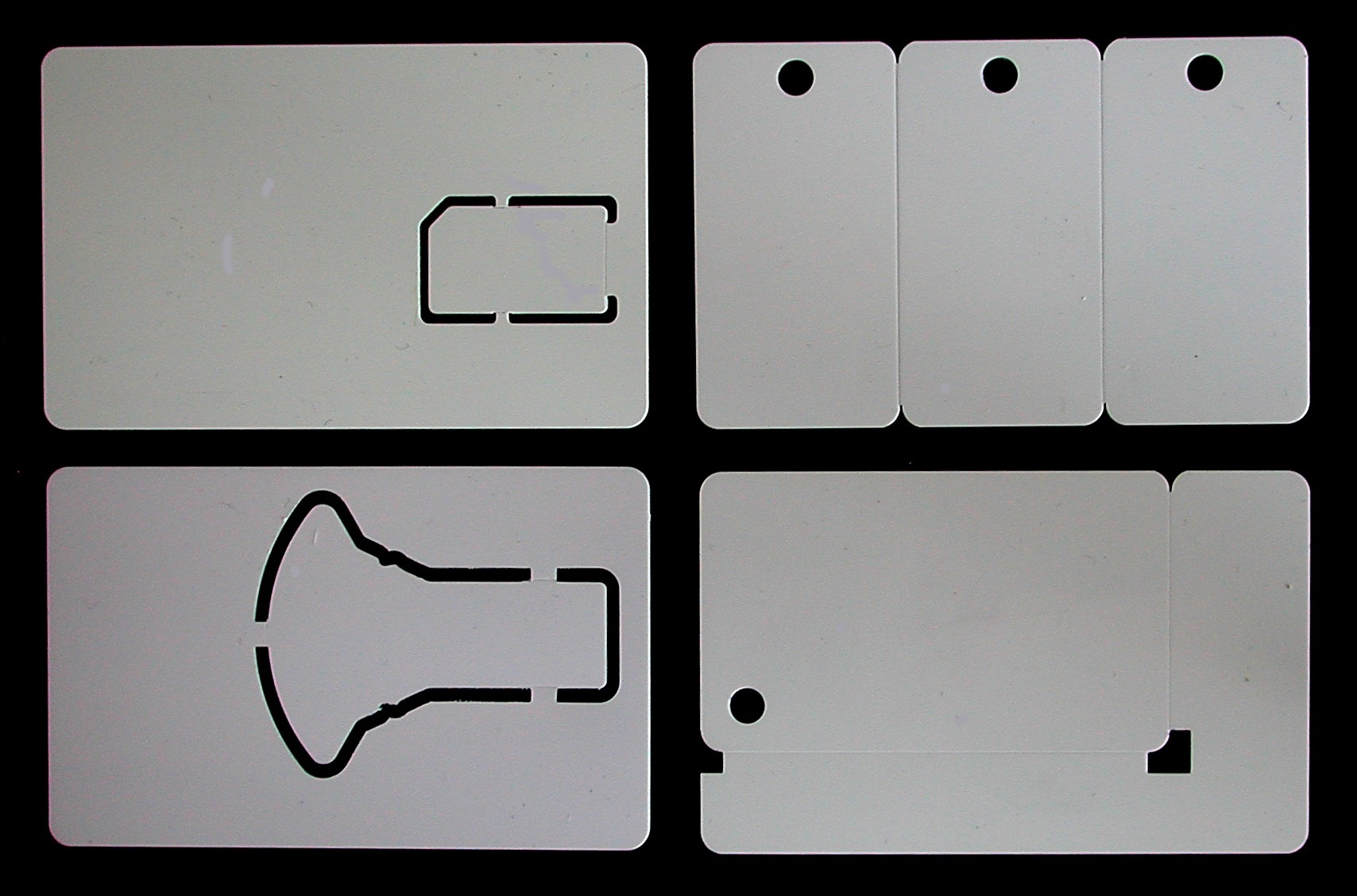

With GSM-SIM card punching, the SIM module contour is punched. Examples are shown in the following picture.

Function

The cards are manually placed into a magazine.

Under the magazine is the feeding unit to transport the cards on a conveyor belt.

The impulse of the feeding unit is pneumatically issued over excenter.

In the first stage, the cards are pulled downwards out of the magazine,

one by one, with suckers. The rest of the card transport happens

through a pneumatic feeder moving the cards to the punching unit.

The feeder is exactly timed to the punch move by a sensor. So the cards

are pricisely placed into punching position.

There are always two cards side by side under the punch tool, so two functions can

be performed simultaneously by one stroke. For example with GSM-SIM cards, the separation lines are

perforated into one card whilst the SIM contour slits are punched into the other. The punch tool is operated by

a hydraulically driven excenter shaft. The finished card is pushed out of the punching unit through the following

card and transported by a conveyor belt to the depot.

An important advantage of our punching unit is that tools may be quickly exchanged if required

(short downtime!).

Technical Data:

- Machine Size: approx. 1500 (L) x 500 (W) x 1500 (H) mm

- Card Standard: ISO 7810/7813, thickness 0.5 – 1.0 mm

- Punch Speed: up to 4500 cards per hour

- Power Supply: Three-phase AC 400 V

- Compressed Air Supply: 6 bar